The COMET Center CDP Center for Digital Production is funded within the framework of COMET – Competence Centers for Excellent Technologies by BMK, BMDW, the provinces of Lower Austria, Vorarlberg and Vienna. The COMET program is managed by the FFG.

The Austrian Center for Digital Production supports companies in the digitalization and automation of discrete manufacturing and production processes.

Special focus is placed on the needs of SMEs and the tasks arising from the processing of small batch sizes.

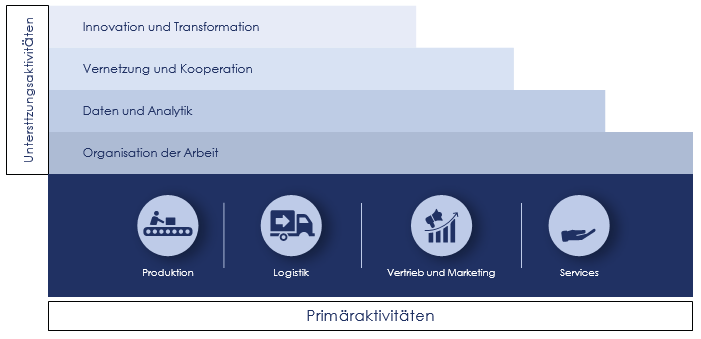

The competence portfolio ranges from the virtual mapping of products and production systems to the automation of design tasks, machine-to-machine communication, including sensor integration, integration with and into IT systems and the consideration of socio-economic aspects.

You can find more information in our new interactive brochure!

M2M – COMMUNICATION – AUTOMATED SHOPFLOORS

In cooperation with our partners, we develop solutions that make the following possible:

- Flexible, reconfigurable automation

- Vertical integration

- Interactive production planning

- Comprehensive access to process data

- Predictive quality assurance

The “Pilot Factory” at TU Wien enables testing and evaluation under realistic production conditions.

DATA DRIVEN PROCESS IMPROVEMENT

Based on real-time data supply at both machine level and the units for resource planning, we develop solutions for

- Optimized, interactive production planning

- Self-learning process optimization (at machine and planning level)

- Resource consumption optimization

- Predictive maintenance

The “pilot factory” allows rapid prototyping and a demonstration of approaches to planning through the use of sample data from typical production situations.